INDUSTRIES WE SERVE

Diverse Industry Solutions

ARIN TECHNOLOGIES brings precision to diverse sectors including aerospace, wind energy, automotive, robotics, shipbuilding, heavy vehicles, and locomotives. Our tailored metrology solutions guarantee excellence, upholding the highest standards in every industry.

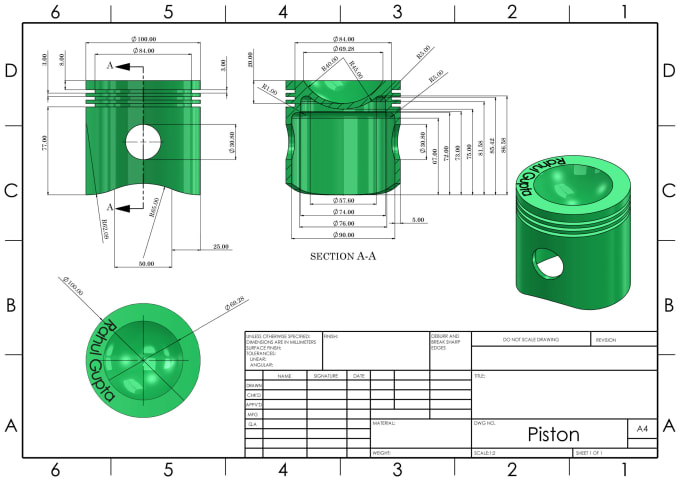

2D Drawings

Arin Technologies values 2D drawings as essential tools for clear communication, technical documentation, and precise manufacturing. These drawings ensure consistency and compliance in regulated sectors like aerospace. They also support cost-effective design iterations, enhancing overall project efficiency and success.

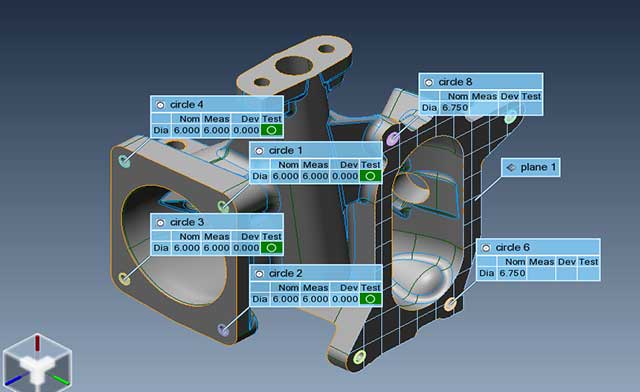

3D Inspection

Arin Technologies employs 3D inspection to boost manufacturing quality. This advanced method uses 3D modelling for precise assessment, uncovering defects not visible in 2D inspections. It’s crucial in industries like aerospace, ensuring products meet specs, reducing errors, and reinforcing Arin’s metrology excellence.

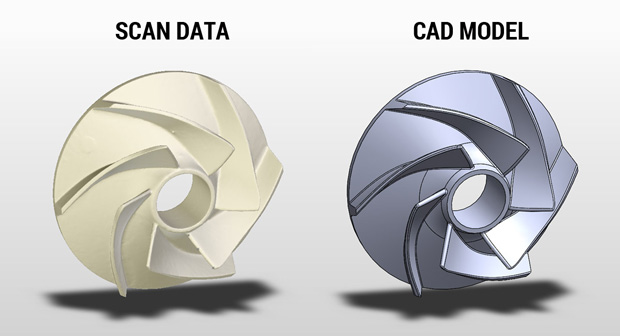

Scanning and Comparison

Arin Technologies relies on scanning and precise comparisons to ensure quality in metrology. Using advanced 3D scanning, they compare real-world objects to CAD models, promptly detecting and correcting discrepancies. These techniques are vital in aerospace and automotive industries, ensuring compliance with rigorous standards.

Reverse Engineering

Arin Technologies excels in reverse engineering, dissecting products to grasp design and manufacturing. They use advanced tech to craft 3D models from physical objects, aiding in design modifications, quality improvements, and part replication. This is crucial in aerospace and automotive industries, allowing Arin to enhance products and stay competitive in precision engineering.

Laser Tracker Inspection

Arin Technologies excels in reverse engineering, using advanced technology to deconstruct and analyse products. They create detailed 3D models and CAD representations from physical objects, enabling design modifications, quality improvements, and part replication. This practice is particularly valuable in aerospace and automotive industries, enhancing products, addressing issues, and sustaining a competitive edge in precision engineering.